Apollo Silicone Sealant A600

Apollo Silicone Sealant A600

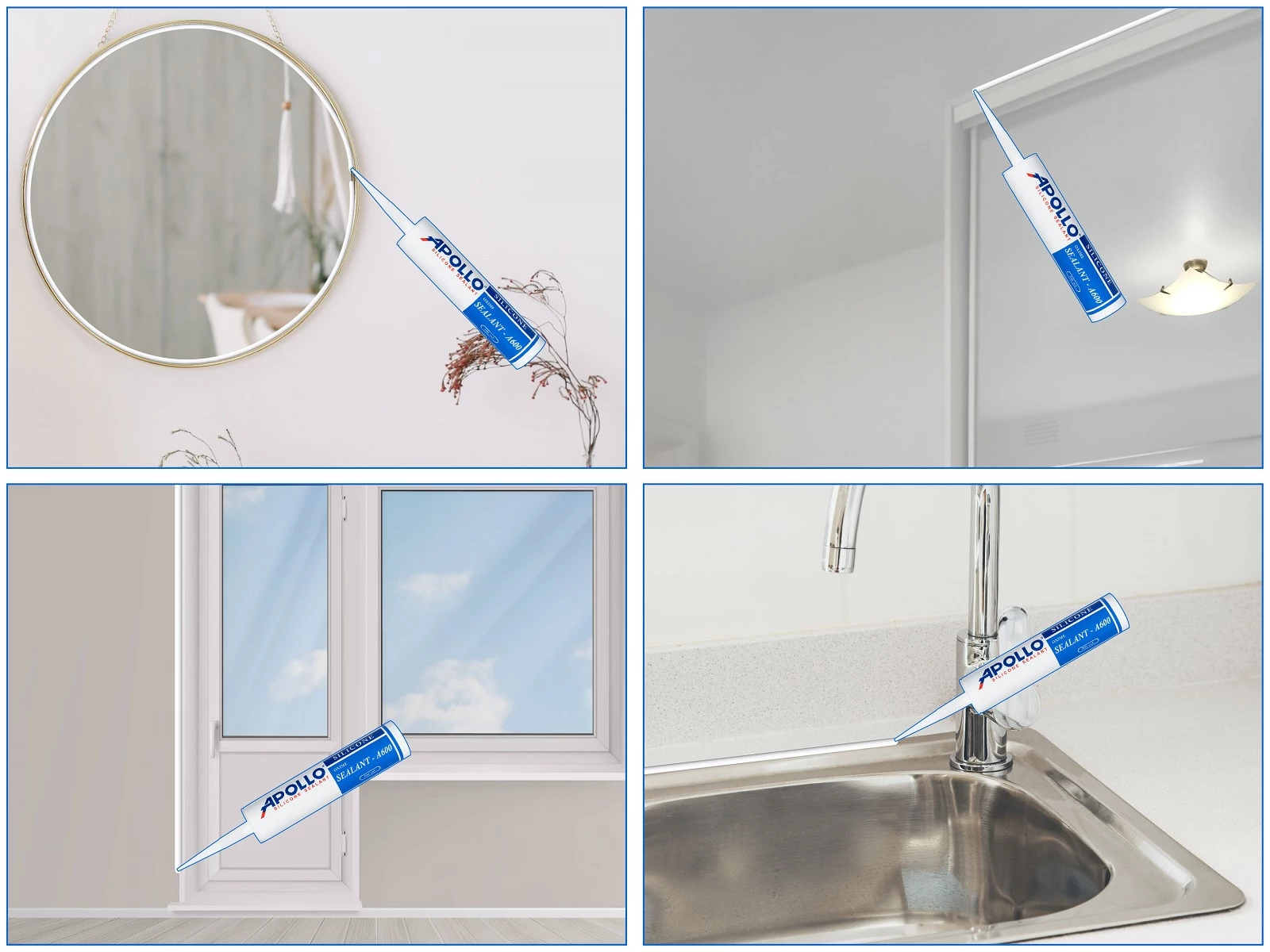

The Apollo Silicone Sealant A600 has been one of the leading silicone adhesives widely trusted in Vietnam for many years. The products under the Apollo brand have gained recognition for their ability to meet the demand for sealing, bonding, and waterproofing various surfaces, boasting high durability, aesthetic appeal, and user safety.

Introduction to Apollo Silicone Sealant A600

The premium-grade sealant, Apollo Silicone A600, is a one-part product with a neutral curing formulation. With superior tensile strength and elasticity, the Apollo A600 adhesive can restore its original shape even when subjected to stretching or compression. Moreover, it can be applied to various types of surfaces.

Product applications

The Apollo Silicone Sealant A600, upon exposure to atmospheric moisture, immediately cures and forms a rubber-like elastic seal. This sealant possesses resilience and can withstand harsh weather conditions, moisture, ozone, and UV radiation.

Additionally, the Apollo Silicone A600 is designed to be used on various materials such as mortar, white cement, and does not corrode metals due to its neutral properties. With its flexible elasticity, it absorbs external environmental vibrations well, making it suitable for complex construction conditions and locations. Furthermore, the Apollo Silicone A600 adhesive can withstand harsh environmental conditions like high temperatures, humidity, ozone, and UV radiation.

Product benefits

The Apollo Silicone Sealant A600 offers users the following benefits:

Weather resistance: Ability to endure sun, rain, snow, ozone, and high temperatures.

Non-corrosive: Being a neutral-cure sealing compound, the A600 silicone adhesive does not corrode metal surfaces.

Recovery after compression: Easily restores shape after stretching or compression.

Convenient application: Ready for use upon provision.

Convenient usage: Simple and easy to handle during usage.

Product Packaging

Similar to other Apollo silicone sealants, Apollo Silicone Sealant A600 is packaged in a 300ml plastic container. The container's surface has a label containing complete information about the composition, instructions for use, manufacturing date, expiration date, volume, and storage instructions for the adhesive product.

Guide for using the Apollo Silicone Sealant A600

Apollo Silicone Sealant A600 has an easy-to-use application method, making it entirely user-friendly for quick home usage.

Preparation steps

Clean the entire surface of the joint where you plan to seal with silicone. Remove all dirt and impediments like grease, dust, water, old sealant layers, or protective coatings.

Product application method

Install the joint support parts, fix the frame, pads, and lining tape together.

Apply a lining of sealant around the edges to make the sealing lines neat. For smooth surfaces, no primer is required. For rough surfaces, Apollo Silicone recommends priming before application.

To ensure good adhesion on both rough and smooth surfaces, check the adhesion before sealing. Contact Apollo Silicone's representative office for specific advice.

Apply consistent pressure to continuously pump Apollo Silicone Sealant A600. Gently press for the sealant to contact the lining material and joint surface before finishing.

After smoothing the joint, immediately remove the lining tape.

Notable points when using Apollo Silicone Sealant A600

Product Limitations

Avoid using Apollo Silicone A600 in the following cases:

Continuous water immersion or below-ground applications.

Inappropriate for heavily corroded or excessively stressed joints.

Use not intended for structural load-bearing purposes.

Not suitable for high-end waterproofing joint connections.

Binding with oil-flowing materials, softeners, solvents, and non-cured pads.

Avoid use without complete air exposure.

Do not bond with copper or copper-containing building materials.

Avoid using on surfaces directly in contact with food.

Does not ensure food and pharmaceutical safety.

Avoid mixing with non-cured sealants other than silicone A600.

Product expiration date and storage conditions

Keep the product at a temperature below 30°C with the bottle cap closed.

The product's shelf life is 12 months from the manufacturing date printed on the packaging as "DATE."

Health and environmental information

Apollo Silicone life adhesive is produced from premium materials from two world-leading groups: Shinetsu (Japan) and Dow Chemical (USA), certified for safety and environmental friendliness. For more information about our products and partners, please visit our website: www.apollosilicone.vn.

Introduction to the Apollo Silicone App

Apollo Silicone brand developed the Apollo Silicone app with various convenient features to meet customer needs. Here is some information about the app:

Updates on customer care policies, events, seminars, competitions, specifically for customers.

QR code scanning feature on the silicone adhesive bottle to verify genuine products and avoid counterfeit ones.

Regular updates on the latest products with useful functionalities.

The Apollo Silicone app is now available on both Android and iOS platforms. Customers can easily download and use it for free. Download the Apollo Silicone app now to experience its convenient features and receive attractive offers!

Summary of Apollo Silicone Sealant A600

With the outstanding advantages highlighted in the article alongside its versatile applications, the Apollo Silicone Sealant A600 is undoubtedly the suitable and best choice for bonding various surfaces and materials. We believe that the excellent quality of Apollo A600 silicone adhesive will provide maximum peace of mind and satisfaction to customers in their construction projects.

- Link copied!