Apollo Silicone Sealant A300 - King of Silicone Sealant

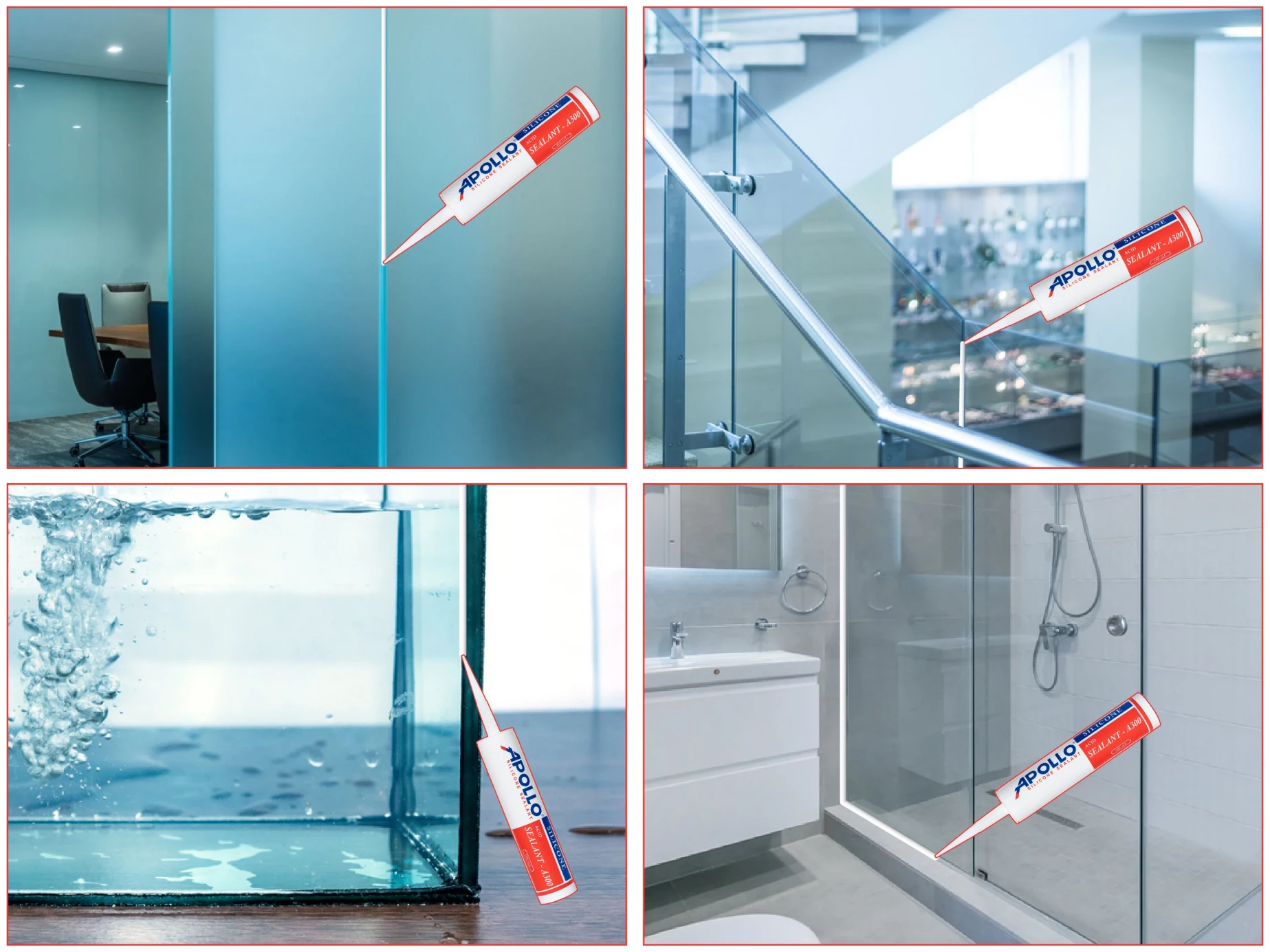

Apollo Silicone offers a diverse and extensive products in the market, catering to a wide range of applications in construction projects. Among these, the Apollo Silicone Sealant A300 stands out prominently, boasting numerous distinctive features that have earned it the trust of many experts and contractors in the construction industry. Particularly acclaimed as the King of Silicone Sealant, Apollo Silicone Sealant A300 is widely utilized in projects involving glass materials.

Introduction to Apollo Silicone Sealant A300

The Apollo Silicone Sealant A300 is an acid-cured silicone sealing compound renowned for its outstanding flexibility and high elasticity. It demonstrates exceptional durability in harsh environmental conditions, including extreme temperatures, humidity, ozone, and ultraviolet rays. Notably, Apollo Silicone A300 maintains its color and resists cracking when used outdoors, enduring even the most severe weather conditions. It exhibits excellent adhesion to most construction materials without the need for a primer.

This product offers remarkable tensile strength and exceptional elasticity, capable of restoring its original shape when stretched or compressed. Due to these superior characteristics, the Apollo Silicone Sealant A300 has earned the moniker "King of Silicone Sealant," dominating the market for silicone adhesives used in bonding glass materials.

Product Benefits

Excellent weather resistance: This product exhibits outstanding weather resistance, safeguarding bonded structures against adverse weather elements.

Strong adhesion and fast bonding: The product ensures strong adhesion and quick bonding time, guaranteeing the quality of glass materials after use.

High restorative ability: Even after being stretched or compressed, the Apollo Silicone Sealant A300 possesses a high restorative capability, maintaining aesthetic appeal and reliable adhesion.

Product Applications

The effectiveness of Apollo Silicone Sealant A300 is best showcased when used for glass joints. Hanging structures also benefit significantly due to its 500% elasticity, making it ideal for bonding glass, window and door frames, non-porous surfaces, certain types of plastics, glass tanks, etc.

Product characteristic features

Apollo Silicone Sealant A300 possesses an appropriate viscosity, enabling easy and uniform application on various surfaces. It does not subsidence after application, ensuring that the product's effectiveness is maintained with high aesthetic appeal.

Especially, approximately 15 minutes after contact with the surface, the product self-cures, facilitating an efficient and quick sealing process. It can be used in environments with surface temperatures ranging from 5°C to 40°C, expanding its application possibilities. It also has a wide heat tolerance from -50°C to 150°C, ensuring consistent performance even in harsh conditions.

Product Packaging Utilizing QR Code Technology

Apollo Silicone Sealant A300 is packaged in a 300ml plastic tube, making the adhesive easy to use and minimizing wastage. The 300ml plastic tube is an optimal choice for product storage and transportation, preventing damage like denting, breakage, or deformation.

Furthermore, Apollo Silicone now incorporates UV QR code printing technology on all product packaging. This allows customers to easily and efficiently verify the product's origin and authenticity quickly. Purchasing genuine Apollo Silicone products has become simpler than ever before.

Guide for using Apollo Silicone Sealant A300

Before using the Apollo Silicone A300 adhesive, it's advisable to prepare a few steps to ensure a smooth bonding process and achieve maximum performance.

Preparation steps

Before using, cleaning the joint surface is crucial. Removing dust, grease, water, old sealant, or any surface coatings enhances the product's effectiveness.

Use solvents like acetone, IPA, xylene, or MEK to clean the surface. These solvents eliminate residues after cleaning, ensuring a clean surface for bonding.

Conduct a test on a small area to ensure optimal adhesion. In some cases, using a primer may increase the silicone adhesive's bonding efficiency.

Product Usage Guidelines

After preparing the surface as instructed, using Apollo Silicone Sealant A300 follow the below method:

Cut the tip of the sealant nozzle at a 45-degree angle to create an appropriate-sized dispensing hole.

Use a silicone gun to apply the necessary amount of sealant onto the joint surface. Use other tools to shape and flatten the sealant.

If excess sealant remains on the surface, remove it using appropriate tools.

Follow the instructions for drying and curing time before further handling or applying pressure on the adhered surface.

Important note when using Apollo Silicone Sealant A300

Before usage, customers should thoroughly read safety information, data sheets, and labels on the product packing.

Product expiration date and storage conditions

To ensure optimal quality, store the Apollo Silicone Sealant A300 at temperatures in 30°C if the tube is unopened. The product has a shelf life of 12 months from the manufacturing date, clearly indicated on the packaging. Adhering to the specified shelf life ensures the product remains in its best condition.

Product limitations

The product is not recommended for continuous water immersion, underground applications, or continuous corrosive environments.

Health and Environmental information

All Apollo Silicone products are manufactured from premium materials sourced from Dow (USA) and ShinEtsu (Japan). These are leading global companies distributing products meeting high safety and environmentally friendly standards.

Introduction to the Apollo Silicone App

Apollo Silicone has developed the Apollo Silicone app with numerous convenient features, catering to customer needs. Here are some details about the app:

Updated information on customer care policies, events, seminars, contests, etc., exclusively for customers.

QR code scanning feature on the silicone sealant bottle to check authenticity between genuine and counterfeit products.

Regular updates on the latest products with useful functionalities.

The Apollo Silicone app is now available on both Android and iOS platforms. Customers can easily download and use it for free. Get the app now to experience its convenient features and receive attractive offers!

Summary of Apollo Silicone Sealant A300 Product

Apollo Silicone Sealant A300 rightfully earns the title “King of Silicone Sealant" with its optimal bonding capabilities across all materials, superior elasticity, and resilience against harsh conditions. Apollo Silicone - Bonding forlife, with reliable adaptability, this sealant creates strong and durable connections, serving as a long-term companion in all life's endeavors.

- Link copied!