Apollo Acrylic Sealant A100

Apollo Acrylic Sealant A100

The Apollo Acrylic Sealant A100 is the premium and water-based acrylic sealant from Apollo. Its exceptional adhesive properties make it suitable for various filling and sealing applications, particularly ideal for cracks and gaps in walls and concrete. This product stands as a reliable choice for projects, ensuring aesthetics and long-lasting results.

Introducing Apollo Acrylic Sealant A100

The Apollo Acrylic Sealant A100 is a special sealant designed for surfaces made of concrete, aerated concrete, gypsum, fiber cement board, ceiling gypsum tiles, aluminum, PVC panels, and wood, especially in areas that don't require significant elasticity.

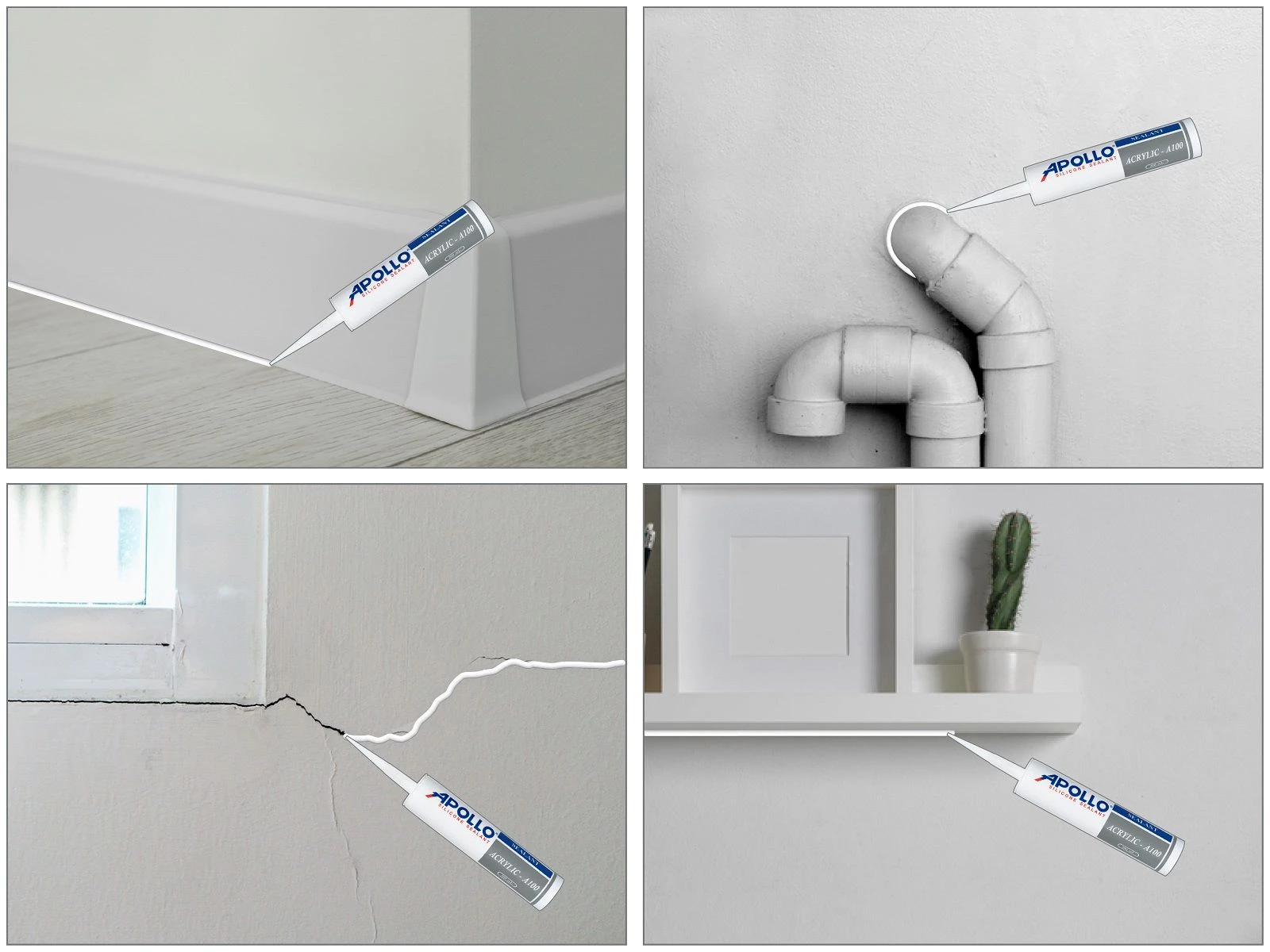

Product applications

The application scope of the Apollo Acrylic Sealant A100 is quite remarkable. This specialized adhesive is perfect for a range of tasks: filling and sealing piping systems, gaps around main doors, windows, inner wall surfaces, and tile joints. Its excellent anti-fungal properties ensure surfaces remain free from stains and discoloration. Moreover, this sealing compound adheres firmly to almost all types of building materials.

Product characteristics

Here are the advantage feature of the Apollo Acrylic Sealant A100:

-

Easy application without complications.

-

Environmentally friendly, containing no harmful solvents, benefiting both health and the environment.

-

Excellent adhesion to various surface types.

-

After complete curing, it allows for painting without any adverse effects.

-

Ideal for cracks and joints that do not require significant elasticity.

Product characteristic features

The product's features include:

Tested at 25°C temperature and 50% relative humidity upon delivery.

-

Chemical base: Acrylic.

-

Subsidence <2mm.

-

Color: White.

-

Surface curing time (minutes): 12.

-

Full drying time: 4mm/day.

-

Construction surface temperature (°C): +5 to +30.

-

Working temperature after curing (°C): -10 to +80.

The curing rate and working time vary depending on temperature and humidity.

-

Specific Gravity (Kg/L): 1.6

After curing - after 28 days at 25°C temperature, 50% relative humidity

-

Hardness measurement, Shore A: 40

-

Elongation capacity (6): +10%

Product Benefits:

-

The product is designed to minimize emissions during curing, contributing to environmental protection.

-

Easy to use upon opening, saving time and effort with its quick-drying ability.

-

Does not contain harmful components, ensuring user safety.

Product Packaging

The product features smart and convenient packaging for easy use and storage. The quality packaging safeguards that offers convenience to users with a 300ml plastic bottle, suitable for various projects and different construction needs.

Guide to using Apollo Acrylic Sealant A100

Before starting to use Apollo A100 adhesive, ensure you have all the necessary tools and prepared surfaces to achieve effective bonding.

Preparation steps

Some essential preparatory steps include:

-

Check the product: Ensure the sealant tube is intact and not damaged before opening.

-

Surface preparation: Remove dirt and anything that might affect adhesion.

-

Testing: We advise you should test sealant at a small area to ensure the product performs well on the surface and achieves the desired results.

-

Prepare necessary tools such as adhesive guns, cutting knives, and cleaning tools.

How to use the product

After completing the preparation steps, follow these instructions to maximize the bonding and sealing performance of Apollo A100:

-

Open the lid and prepare the adhesive pump. You can use an adhesive gun for specific bonding points or a brush for different surfaces and areas needing adhesion.

-

Remove excess adhesive from the surface after completing the bonding process.

-

Allow the adhesive to dry and set for the required time before further use or manipulation.

Some notes when using the Apollo Acrylic Sealant A100

Product expiration date and Storage Conditions

The product has an expiry of 12 months from the manufacturing date in its sealed, unopened packaging. It should be stored in a dry, cool place, with storage conditions ranging from 5 to 27 degrees celsius and humidity between 30 to 70%. Make sure to seal the lid tightly after use to prevent the adhesive from drying out.

Product Limitations

-

The product can be painted over, customers should thoroughly check the paint's compatibility when in contact with the sealant.

-

It may change color when exposed to certain chemicals, high temperatures, UV rays (especially the white color). However, color changes only affect aesthetics and not entirely the technical properties or durability of the product.

-

Avoid using Apollo A100 on glass, floor joints, sanitary areas, marble, natural stone, etc.

-

Do not use for water pressure-bearing joints or those continuously in contact with water.

-

Avoid use on bitumen surfaces, natural rubber, EPDM plastic, or materials that exude oils, resins or contain solvents because they may affect the sealant.

-

Do not use Apollo A100 in areas where the temperature changes too much (temperature changes during the curing process).

Health and environmental information

All Apollo Silicone products are manufactured using premium materials from two leading global conglomerates, Dow and ShinEtsu. These materials are certified safe and environmentally friendly. For further details about our products and partners, please visit our website at www.apollosilicone.vn.

Introduction to Apollo Silicone App

We have developed the Apollo Silicone app with multiple convenient features, catering to customer needs. Here are some role of the application:

-

Updates on customer care policies, events, seminars, contests, etc., exclusively for customers.

-

QR code scanning feature on silicone sealant bottles for authenticity checks between genuine and counterfeit products.

-

Regular updates on the newest products featuring useful functionalities.

Apollo Silicone app is now available on both Android and iOS platforms. Customers can easily download and use it for free. Download the Apollo Silicone App now to experience useful features and receive many attractive incentives!

Summary

Dubbed with the slogan "Apollo silicone - Bonding for life". The Apollo Acrylic Sealant A100 product has been designed to optimize its important contribution to the construction of buildings and living spaces.

- Link copied!